Servo Energy Saving Injection Molding Machine

Servo energy saving injection molding machine output power changes with the loading changing. There’s no extra waste of power. The motor doesn’t work while cooling, electricity consumption is 0. As compared with the tradition injection molding machine, the servo machine can save electricity 20%-80% that brings you excellent profit.

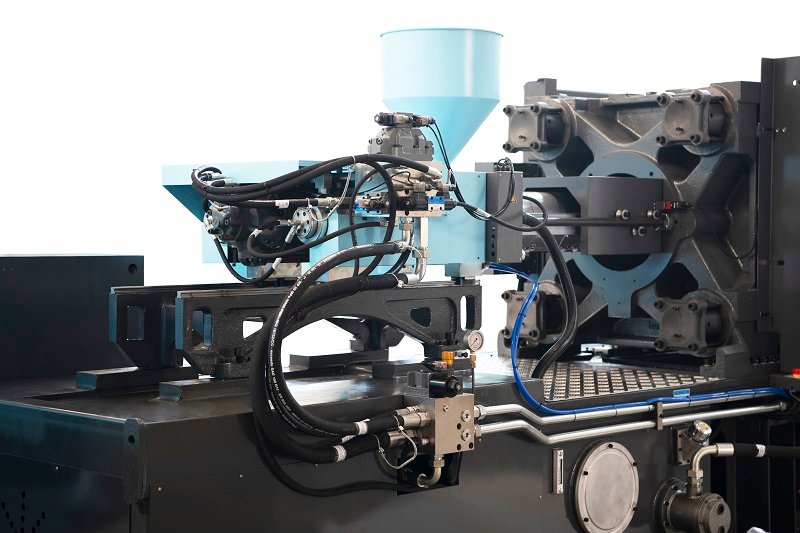

Injection Unit

Injection unit applies double guide post support, equip with fast and strong dual-cylinder balancing injection structure.

- Optimized design screw set, achieve excellent plasticizing effect.

- Using high quality nitride alloy or chrome coated screw and nitride barrel.

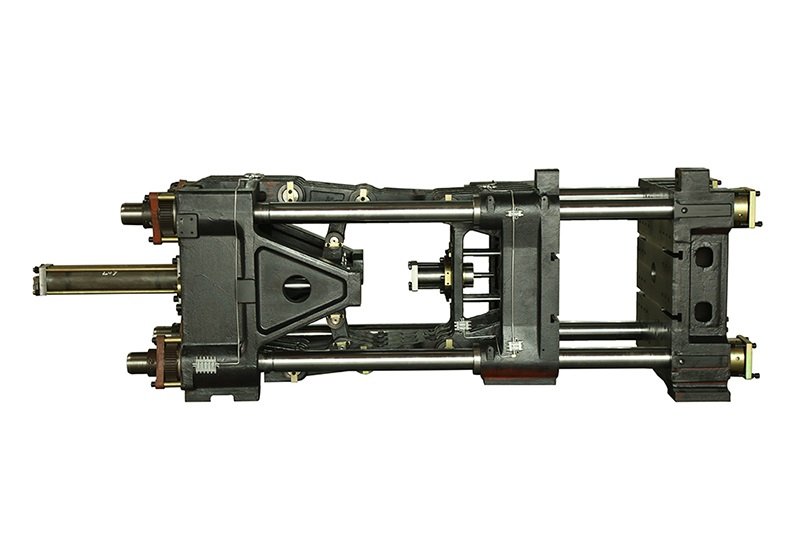

Clamping Unit

Hydraulic (optional), mechanical and electric triple inter-locked safety device, mould close is not realized when open any one of the safety door.

- Low pressure mould protection device, protect mould from damage due to any foreign objects.

- Strengthen moving platen wear

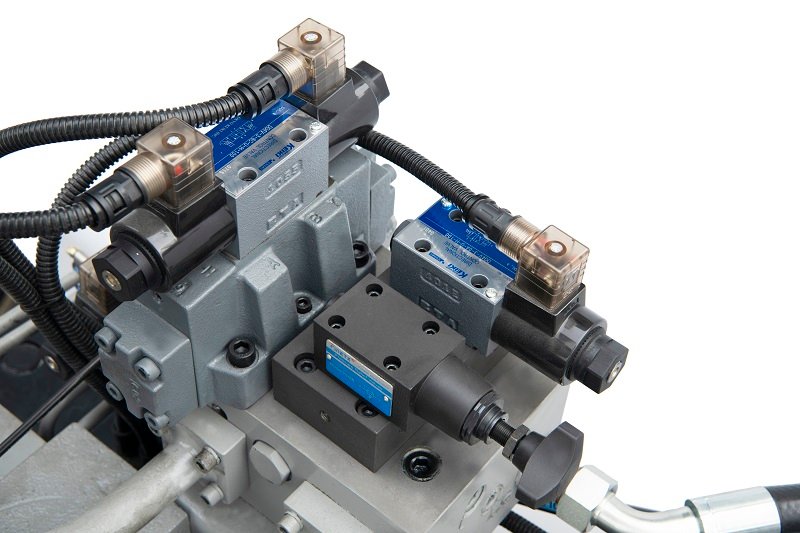

Hydraulic Unit

High precise, high response hydraulic control system.

- Using world famous valves to control injection molding actions precisely, make the system performance stability and reliability.

- Main hydraulic components, sealing rings and high pressure flexible hose are world famous brands.

Electric Control

- TFT LCD color display Using high speed DSP processor, time control precision reaches

- High precise displacement transducer system, control precision

- Using fuzzy prediction technology, temperature control precision

- Multi input/ output interface, the interface function can be setting as demand.

- With output programmable function

- Support USB and network interface (optional)

- Parameter data lock protection, with auto save function in case accident power off

- Big data storage capab